Accueil

>

Bienvenue sur notre blog

>

Wrought Iron, Cast Iron, and Mild Steel The Differences and History of Three Historic Metals

Wrought Iron, Cast Iron, and Mild Steel The Differences and History of Three Historic Metals

par Maddison Nedrow sur Jun 03, 2024Choosing between wrought iron, cast iron, and mild steel can be confusing. Each metal has unique properties and historical significance carefully developed by blacksmiths over the centuries. Let's explore these fascinating materials and their roles in history.

Wrought Iron

A Storied Past

Wrought iron is one of the oldest forms of iron used in blacksmithing for weapons, construction materials, and tools. It contains less than 0.8% carbon and is known for its toughness, malleability, and ease of welding. Resistant to corrosion and boasting good ductility, it's venerated by blacksmiths and artisans alike.

Unique Characteristics

Wrought iron's high slag content (up to 2%) makes it different from modern standards. This fibrous slag protects against oxidation and pitting while creating a woodgrain-like pattern that adds to its artistic appeal. Historically, wrought iron was widely used for structural beams, hardware, and ornamental structures until the mid-1800s.

Modern Usage

Today, true wrought iron hasn't been produced widely for over 100 years due to high production costs and its structural inferiority to mild steel. Most products marketed as wrought iron today are actually mild steel made to mimic wrought iron. If you're looking for authentic wrought iron without the high price of antiques, brands like Old West Iron offer replicated products (See our wrought iron patina on our texture and finish guide).

Cast Iron

Old West Iron's Romantic Cast Iron Corbel

Casting a Legacy

Cast iron is created by pouring molten material into molds to form tools or decorative pieces. It contains 2.1-4% carbon and 1-3% silicon. This composition makes it ideal for molding due to its fusibility. Cast iron is hard and brittle, and it is not malleable. Unlike wrought iron and mild steel, it cannot be shaped with heat, tools, or hammers.

Strengths and Weaknesses

While cast iron is excellent under compression, it fractures easily under excessive tensile stress. This makes it ideal for specific applications but unsuitable for others.

Mild Steel

Old West Iron's French Empire Faux Hinge Strap shown in Wrought Iron Patina finish

The Modern Marvel

Mild steel, also known as plain carbon steel or low carbon steel, contains 0.05-0.3% carbon. It's the most commonly used metal in modern times, having replaced wrought iron in manufacturing in the mid-1800s due to better pricing and durability.

Versatility and Performance

Mild steel is known for its low cost, high tensile strength, corrosion resistance, and good ductility. It can also be finished to replicate wrought iron, making it a versatile choice for various applications.

Use in Historical American Blacksmithing

Colonial Blacksmiths

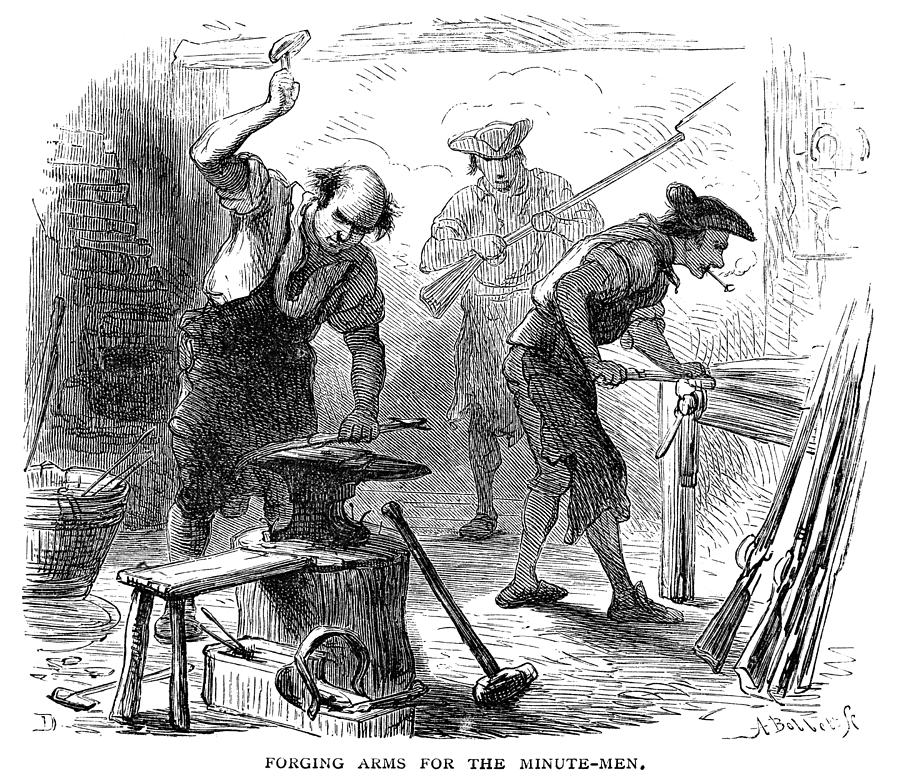

Before the widespread use of mild steel, colonial blacksmiths played a pivotal role in their communities. They created everything from horseshoes and farm tools to nails, locks, and window grates. Most colonial blacksmiths spent the majority of their working hours making repairs, unless they were master craftsmen specializing in items like swords. The ingenuity of colonial blacksmiths contributed heavily to the industrial revolution, which ironically led to the decline in demand for genuine blacksmithing.

Civil War Era Blacksmithing

During the Civil War, blacksmiths traveled with armies and upheld an essential role in the survival and day-to-day life of troops. They used a traveling forge, a compact wagon with a forge and storage space for necessary tools. Blacksmiths were called on to forge and repair weaponry, horseshoes, wagon and cannon wheels, railroads, trains, and other metal necessities. Known for their resourcefulness, they often used discarded pieces, such as wagon wheel treads, to forge new items like horseshoes during leaner times.

Wild West Blacksmiths

In the Wild West, blacksmiths were crucial community members. They forged and repaired horseshoes and wagons, making travel possible in frontier towns far from others. Many skilled blacksmiths were also skilled gunsmiths. Blacksmiths forged important tools for farmers, ranchers, and miners and created various household and construction necessities. Many treaties between Native American tribes and the U.S. government stipulated that blacksmiths would be available at army forts to provide their services in making and repairing tools.

Understanding the differences between wrought iron, cast iron, and mild steel gives us a deeper appreciation for the skill and craftsmanship of historical blacksmiths. These metals, each with unique properties and historical significance, have shaped human history in countless ways. If you're interested in learning more about historical blacksmithing and exploring authentic wrought iron products, visit our blog at Old West Iron.

Maddison Mellem

Old West Iron

p- (844) 205-7266

f- (844) 205-7267